Placement Of Sheathing Clips For Roofing

Not always required but a good idea.

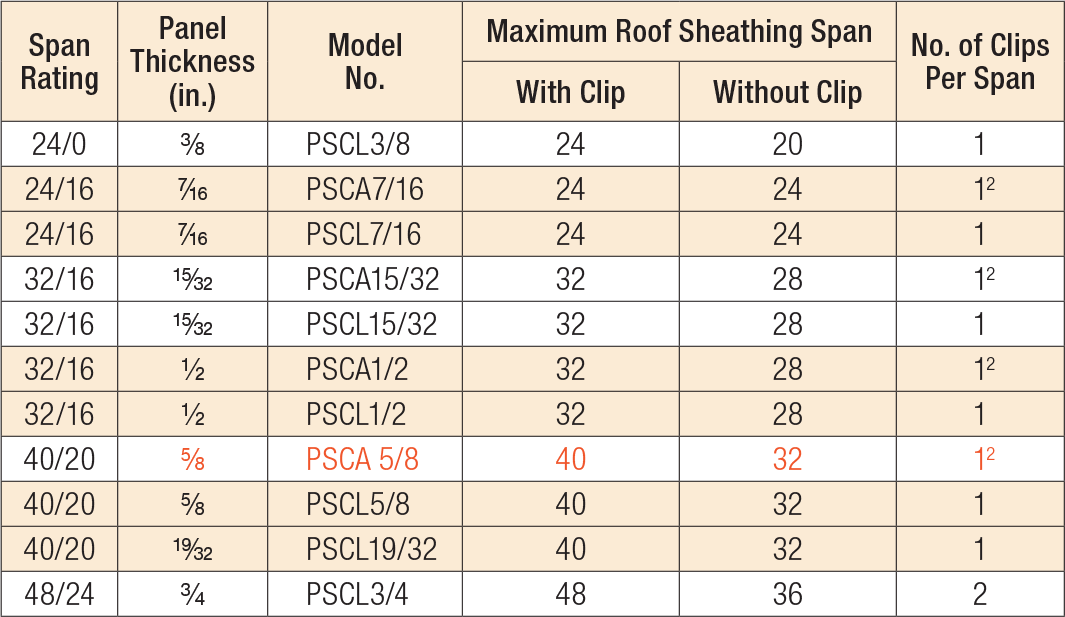

Placement of sheathing clips for roofing. Never attach roof sheathing with staples. Edge clip requirements depend on the relationship of the panel span rating to the actual distance between roof framing. 8d ring shank nails should be used instead. Roof sheathing panel spacing hints.

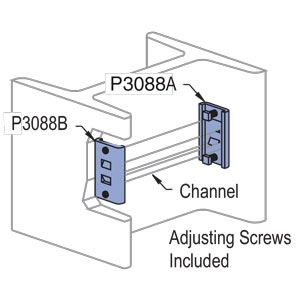

Spacer type panel edge clips are available from some manufacturers. Doing this means you can go to the hardware store and be sure that you are buying the right amount of clips. Simpson strong tie panel sheathing clips are used to brace unsupported sheathing edges and provide a 1 8 gap to address shrinkage and expansion of roof sheathing. H clips provide additional stiffness between bearing points for the unsupported edges of wood panel plywood or osb roof sheathing along with the necessary 1 8 gap for expansion as shown below illustrated on a bag of simpson h clips.

Keeps panels even for a level structural plane. For improved performance consider thicker roof sheathing panels panel edge clips or panels with tongue and groove edges. Plywood clips also referred to as h clips or panel edge clips are small metal brackets placed between the unsupported edges of plywood sheathing to effectively reduce the support spacing and stiffen the plywood. The clips are inserted over the edges of the adjacent plywood panels to reduce deflection of the panel edges between the framing members and are most commonly used for roof sheathing.

Some older h clips do not provide a built in gap. Examine your roof for diagonal beams. Use a 10d box 0 128 inch by 3 inch nail as a spacer to gauge 1 8 inch edge and end spacing between panels. Sheathing should be a minimum of 19 32 inch thick.

This is to allow for adequate roof cavity ventilation. Space between plywood panels as recommended by the american plywood association. Generally 12 15mm ply is the most commonly used thickness. Roof sheathing comes in grid marked 4 by 8 foot sheets and should be installed perpendicular to the frame.

A 1 8 inch space between adjacent panel end and edge joints is recommended unless panel manufacturer indicates otherwise. Check building code requirements for installation of panel edge clips. The typical thickness range for sheathing is 3 8 to 3 4 inch. You need to get into the attic of your roof using a ladder and inspect the connections between the diagonal beams and horizontal beams.

Quick installation no nails required.