Phenolic Foam Roof Insulation Corrosion

The phenolic foam roof insulation turned out to have a critical flaw.

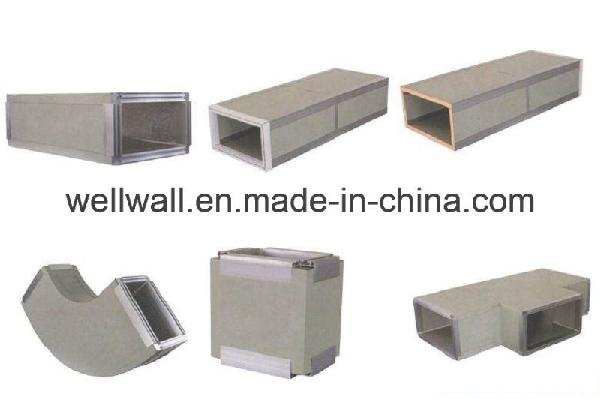

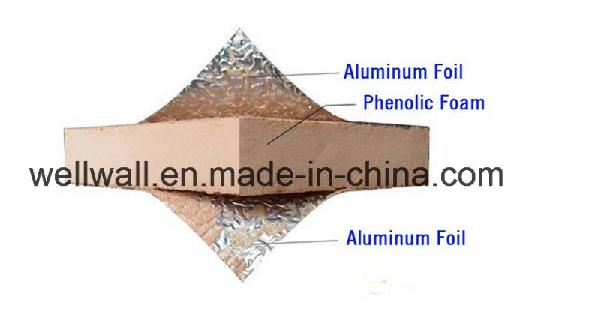

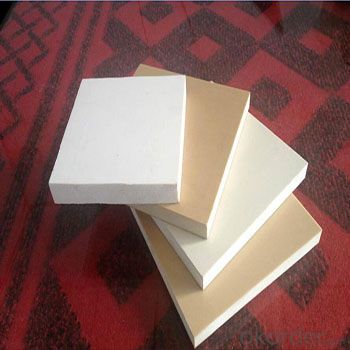

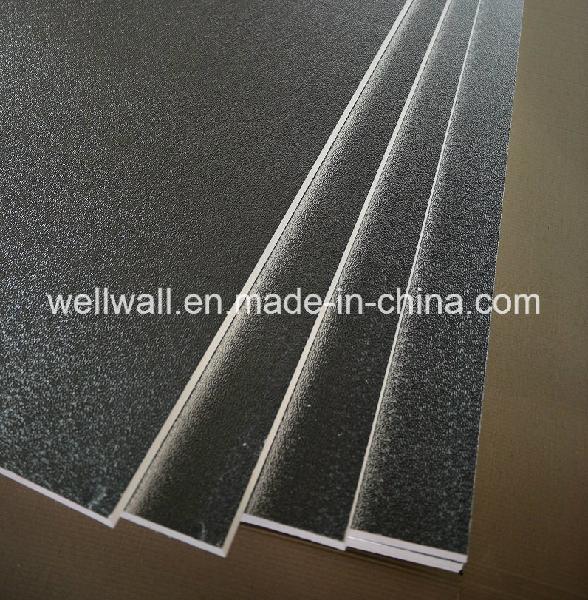

Phenolic foam roof insulation corrosion. W t phenolic foam panel 65kg m3 5 nominal densities 20 30mm thickness cfc hcfc free rigid phenolic insulation core with ozone permeability potential 80 micron aluminum foil facing both sides. Once a property is identified as part of the class action lawsuit it becomes an issue should the. Trymer supercel phenolic insulation is a closed cell rigid phenolic foam insulation supplied in the form of large buns for fabrication into pipe shells curved segments sheets tank and vessel coverings and other shapes for a variety of thermal insulation applications. The rooftop of the test hut where 8 different types of phenolic foam rigid insulation underwent a corrosion test.

Corrosion science is an exceptionally complex subject and the corrosion process takes many forms depending on a range of factors such as the presence of inclusions or surface contamination on the. The phenolic insulation also has a history of crumbling and easily crushes when walked on leaving a residue on the decking. The corrosion created the potential for equipment or people to fall through compromised areas. These photos show the inside of the fraunhofer rooftop test hut and show how water is delivered to the roof system to load the installed phenolic foam rigid insulation with moisture.

Wt phenolic foam is a closed cell type rigid foam made of phenolic resin and flame retardant foaming agent curing agent and other additives. In order to have corrosion three things are required oxygen moisture and a catalyst. 1 the discovery of corrosion of the. This residue is present regardless of whether the insulation has been crushed or not.

Phenolic foam insulation used to be available in board form but today is only sold as a type of foamed in place insulation. Used extensively throughout north america in industrial buildings and warehouses from the early 1980s to the early 1990s because of its high r value and low price phenolic foam has major drawbacks says halcrow yolles project manager. Judging by the building s age and structure the engineers believed phenolic foam insulation was the source. While roof systems containing phenolic foam roof insulation may be in good shape it is important to repair and remediate decks as soon as possible.

Phenolic foam these questions usually refer to its use on copper pipework. It has a very low thermal conductivity and an exceptionally low flammability. When it was installed over a lightly primed painted metal deck any water in the roof system from above moisture from operations or humidity within the building activated chemicals in the phenolic foam which caused corrosion of the metal deck.