Oxy Acetylene Vs Tig For Auto Sheet Metal

It allows you to cut steel sheet bar and plate and is essential for a variety of heating tasks from releasing frozen nuts and bolts to.

Oxy acetylene vs tig for auto sheet metal. Oxy acetylene welding and sheet metal. Gas welding is my first choice because the metal stays fairly soft and workable and. These are older methods of joining thin metal sections that still have some application in today s world of mostly electric welding. This is an older type of method that is rarely used today.

Meanwhile plasma cutting cuts through conductive material by using a jet of plasma and an electrical charge. Oxy acetylene is the process of using a high temperature heat source usually a torch to heat metal. See all 26 photos. The tig is a non starter for hot bending annealing normalizing 4130 brazing silver brazing and soldering.

If you can get your tig out to the yard to fix them. And this welding process is still very popular today mainly because it does not require much equipment and does not require power. A good welding course at a vocational school will have you started down the path of mastering tig techniques. Then oxygen is streamed onto the metal burning it away as a metal oxide.

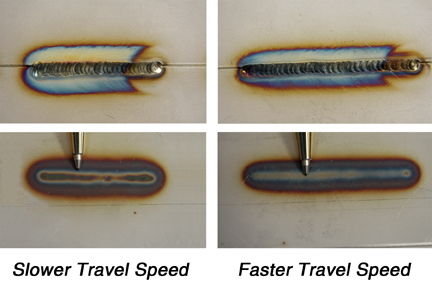

Oxy fuel or oxy acetylene welding are gas welding procedures that were invented in the early 1900 s. And forget trying to use your tig in windy conditions. The best way to reverse it is to hammer on dolly on the weld to stretch the metal back out. For instance it is considered prone to corrosion particularly in areas where it can attract moisture.

Oxy acetylene gas welding brazing and braze welding. Panel or fender flare on a car i use either oxy acetylene gas welding or wire feed mig welding in that order of preference. Tig welding is great but few do it yourselfers have a tig welder so we ll stick with the first two.